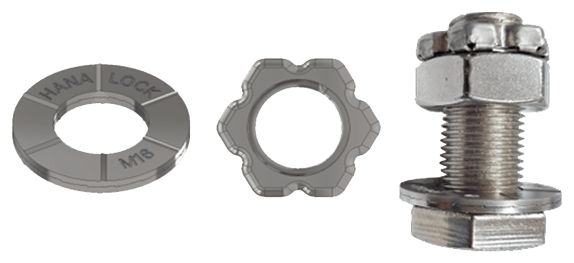

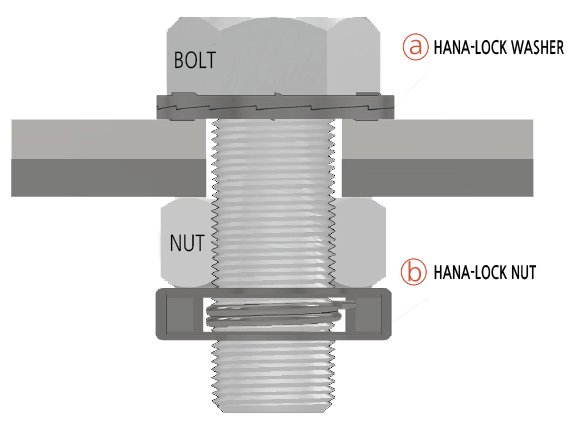

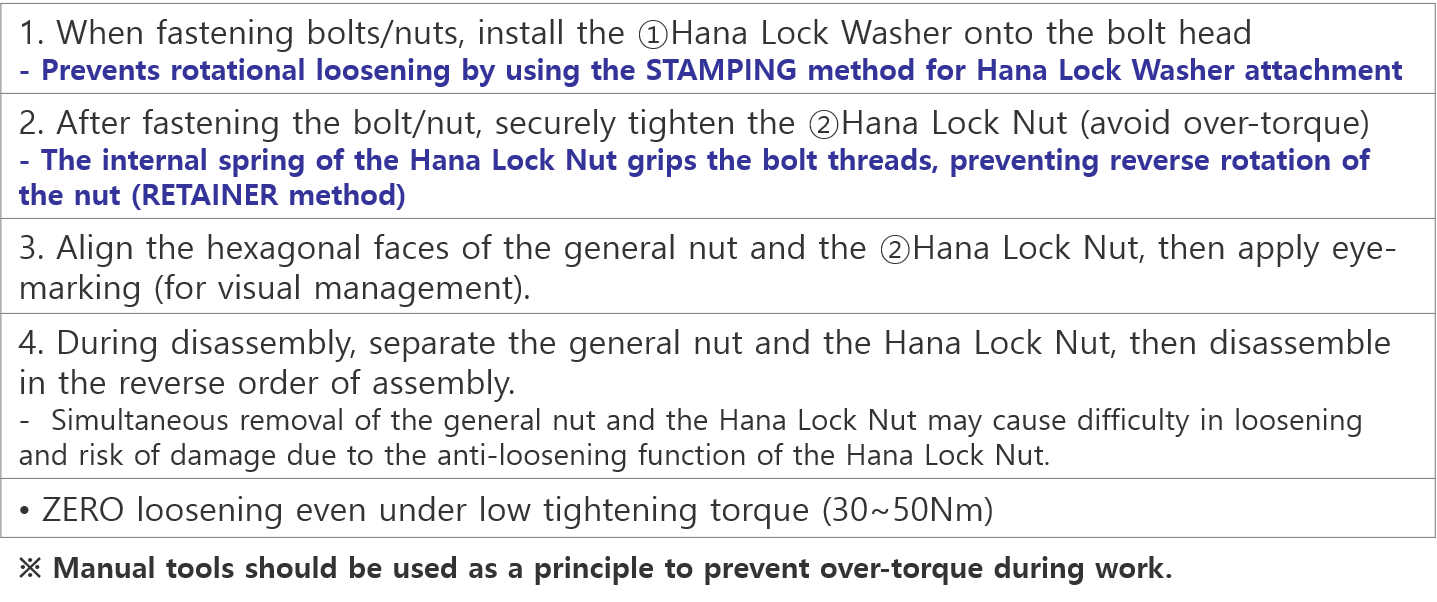

Hana-Lock Washer & Nut

set a new standard for safety and quality

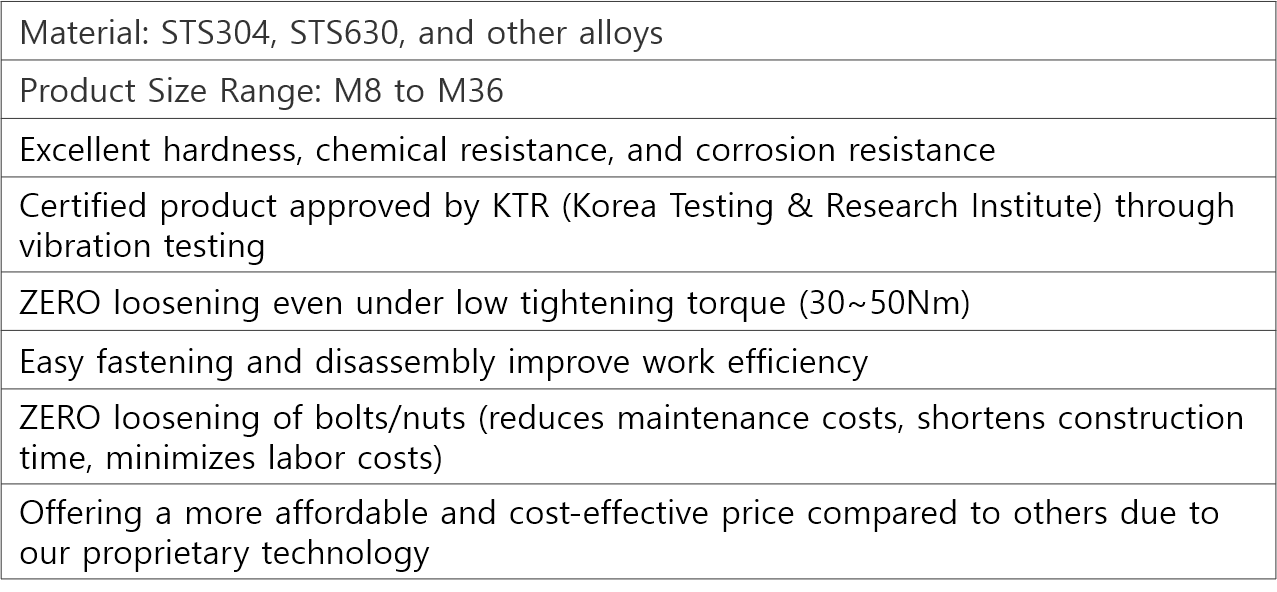

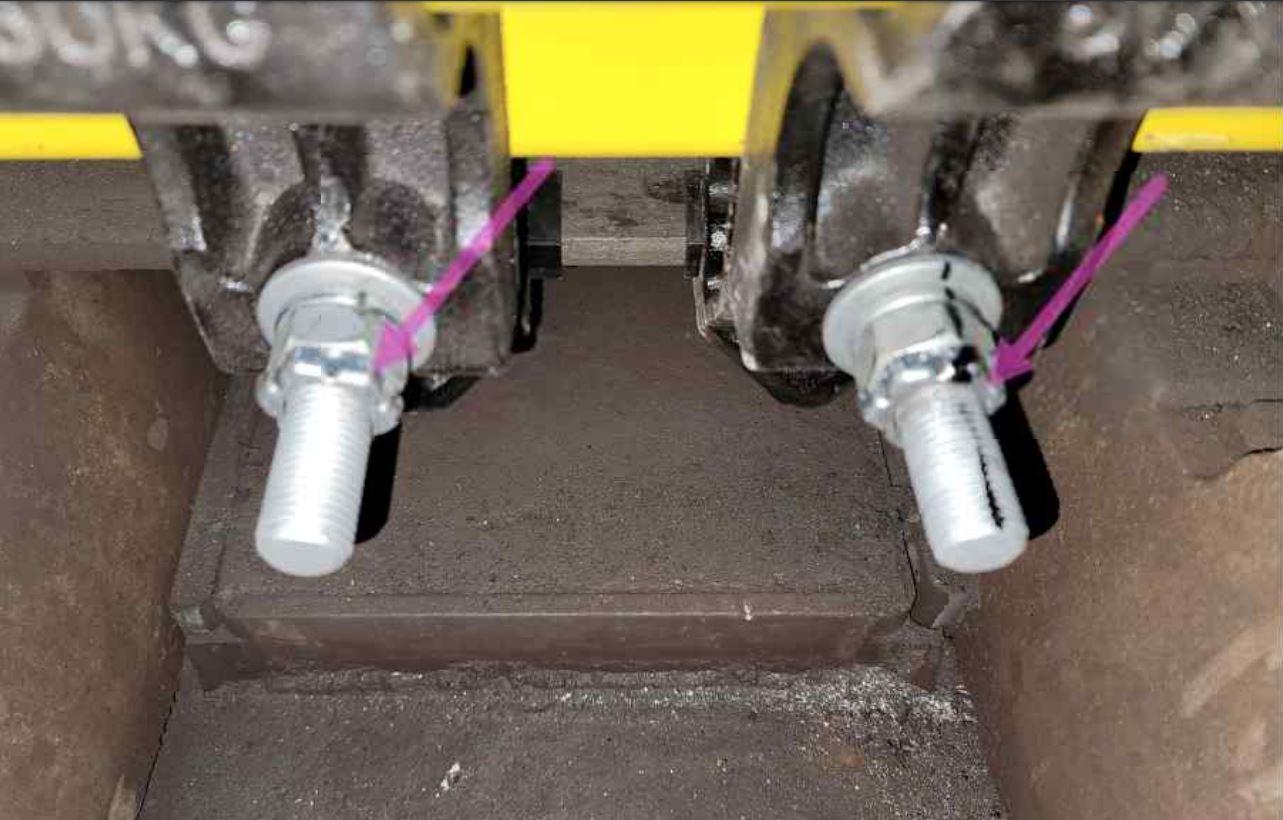

• In all industrial sites, the natural loosening phenomenon of machinery, equipment, and piping equipment steel structures, or the stress caused by the pulsation of fluids and gases flowing inside the pipes due to the vibration of motors or pumps, weakens the bonding strength of bolts/nuts, causing the LEAK phenomenon, which not only causes damage to expensive machinery and equipment but also causes enormous economic losses, and can lead to fatal accidents due to the leakage of chemicals and hazardous materials. Therefore, safe bolt/nut loosening prevention products are needed in all sites.

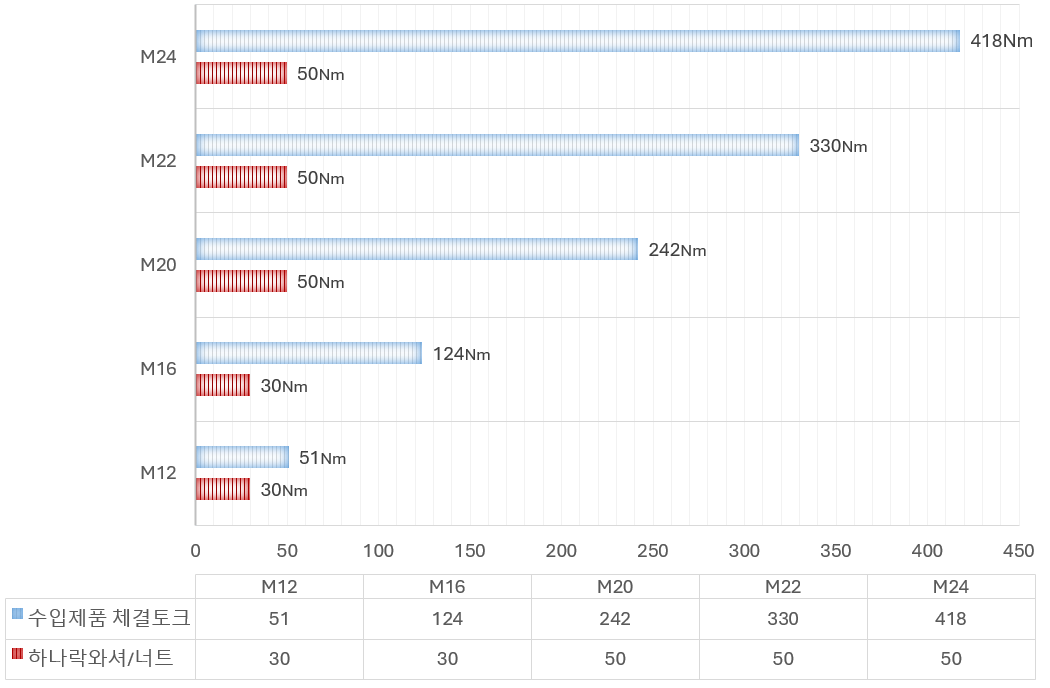

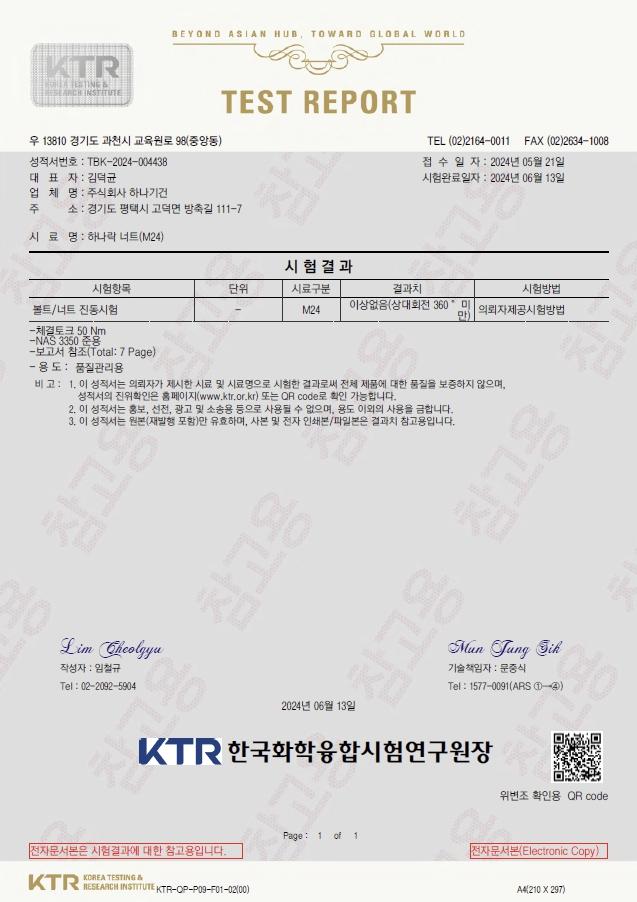

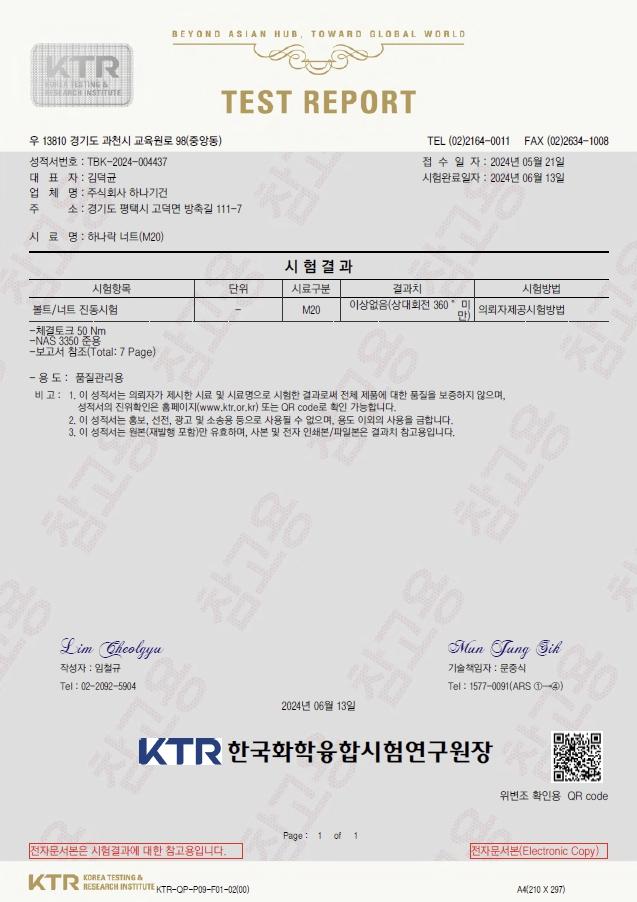

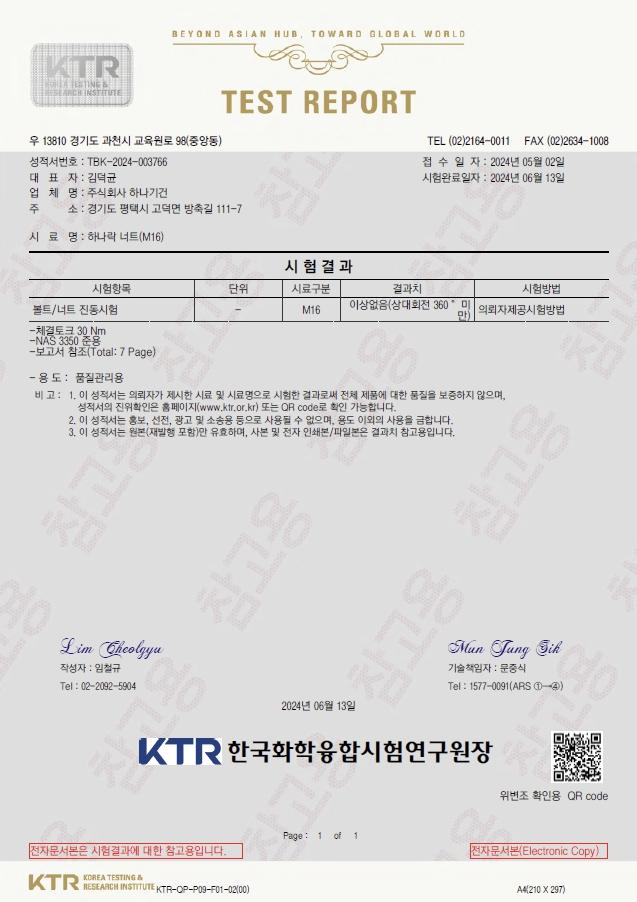

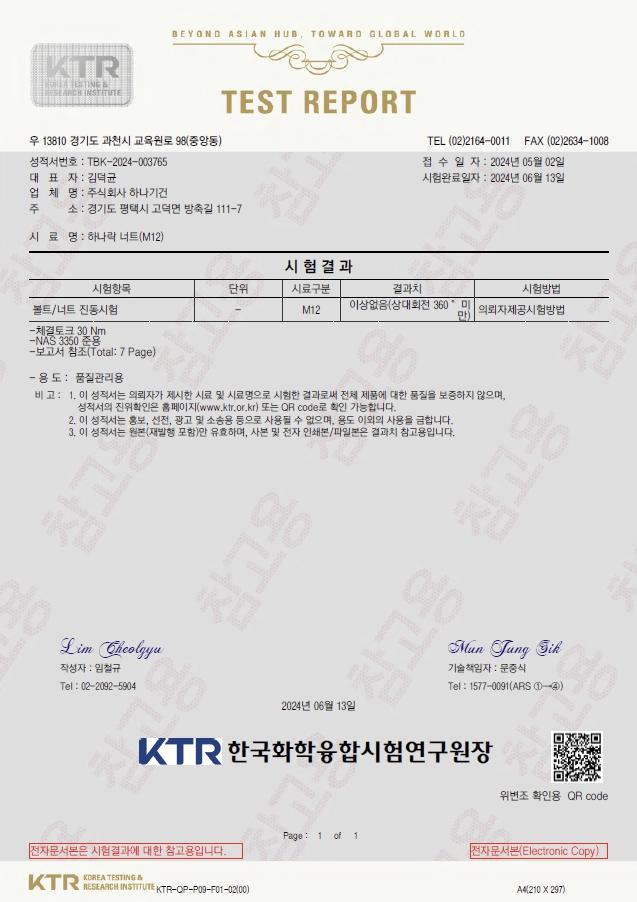

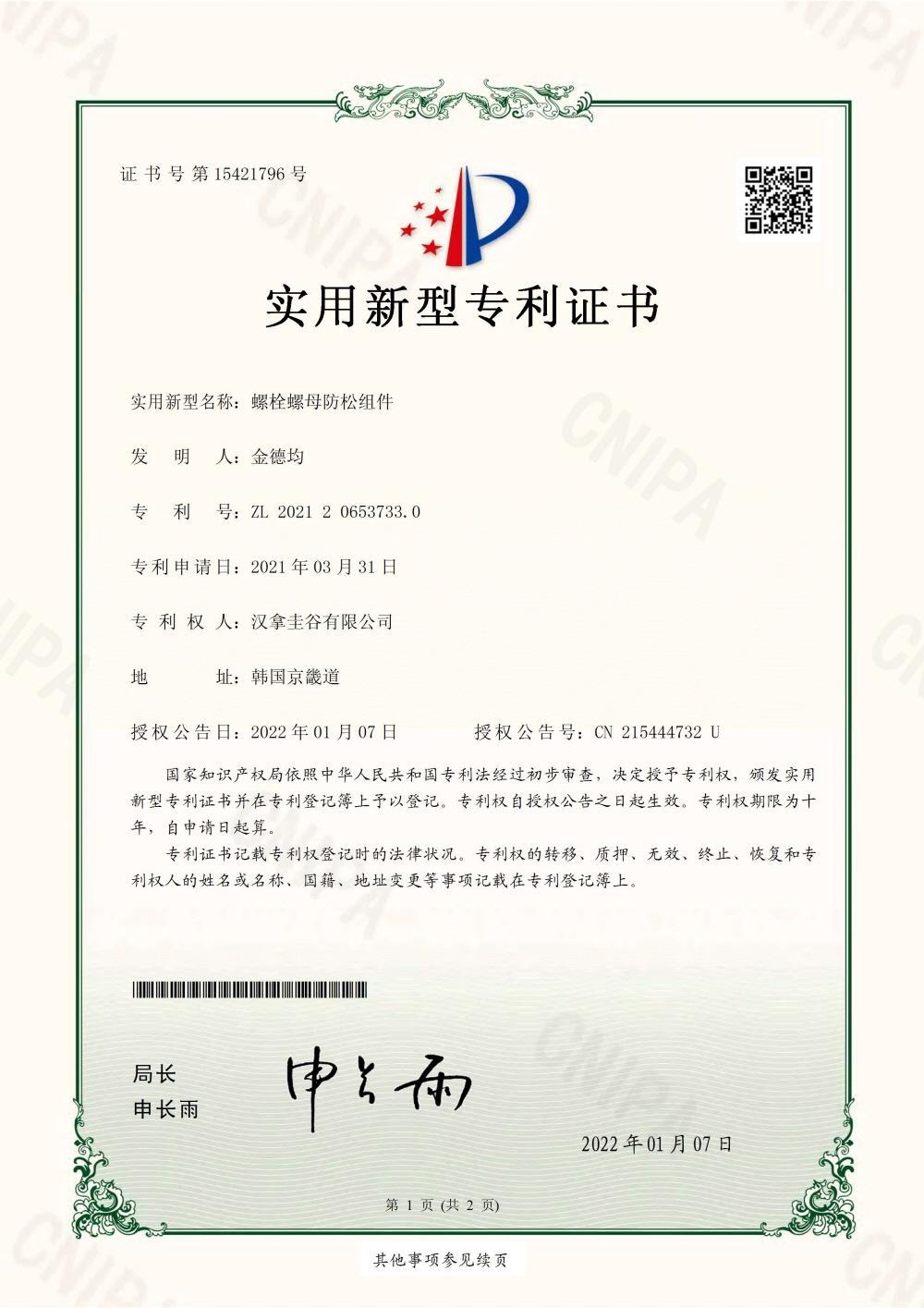

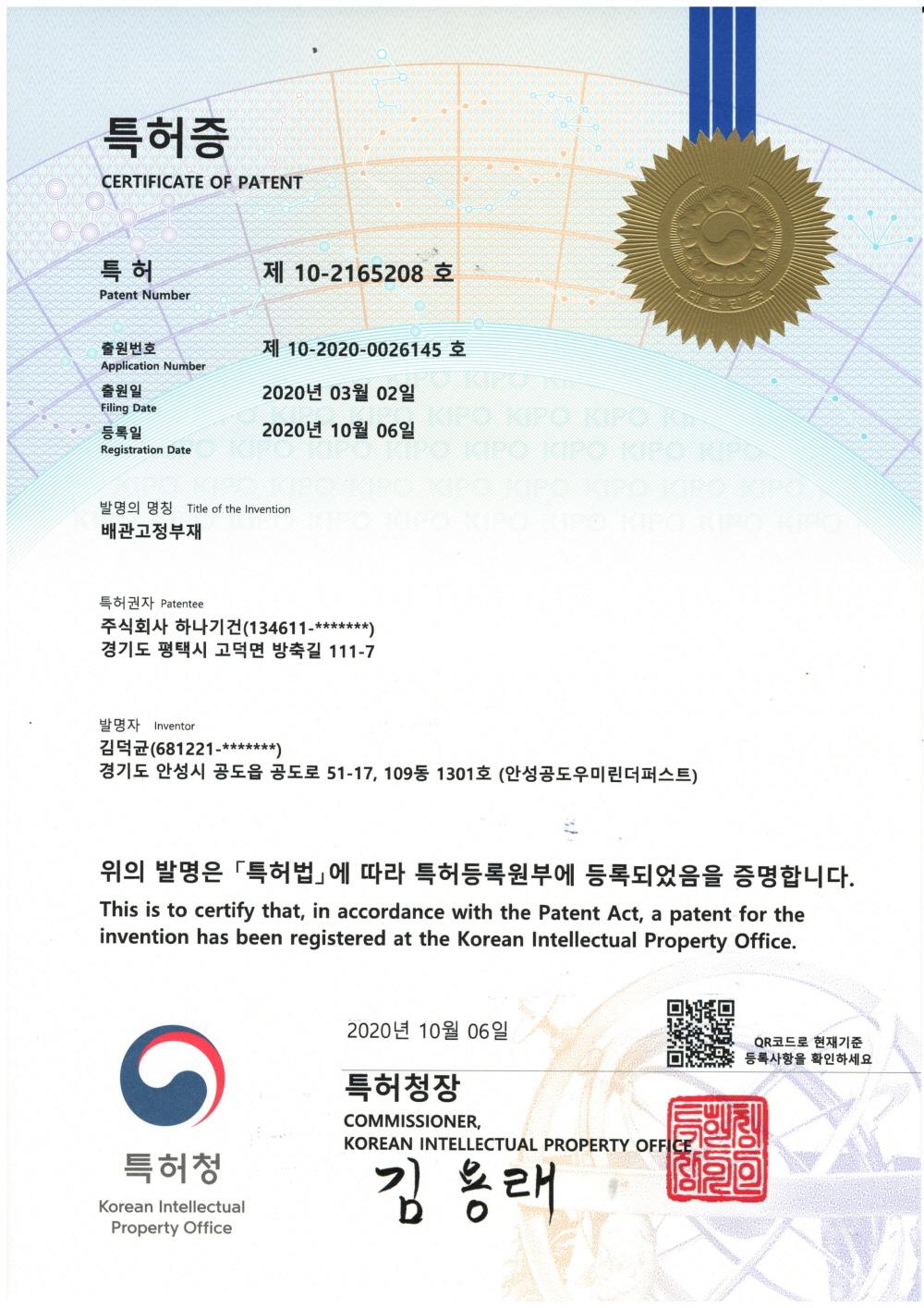

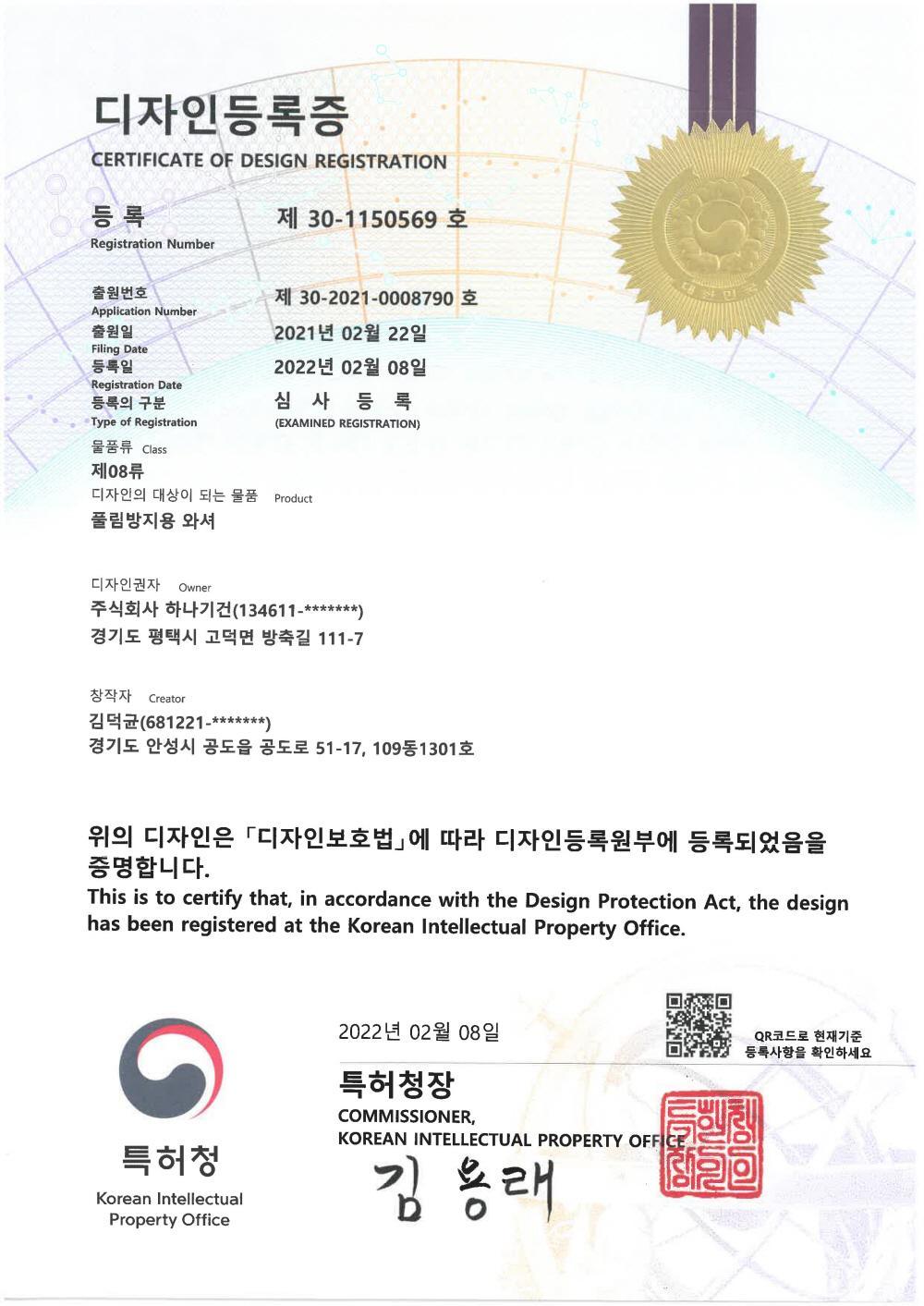

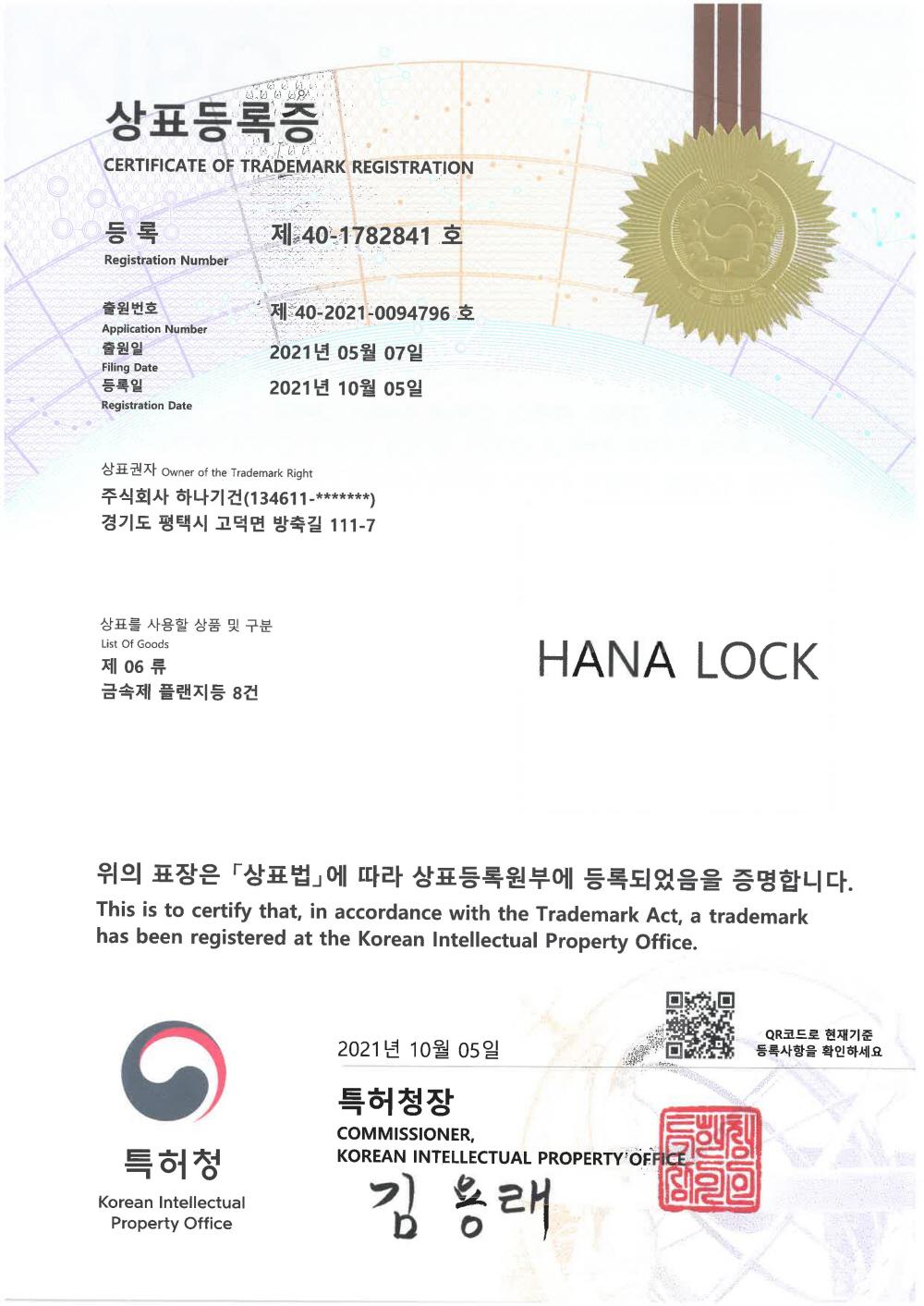

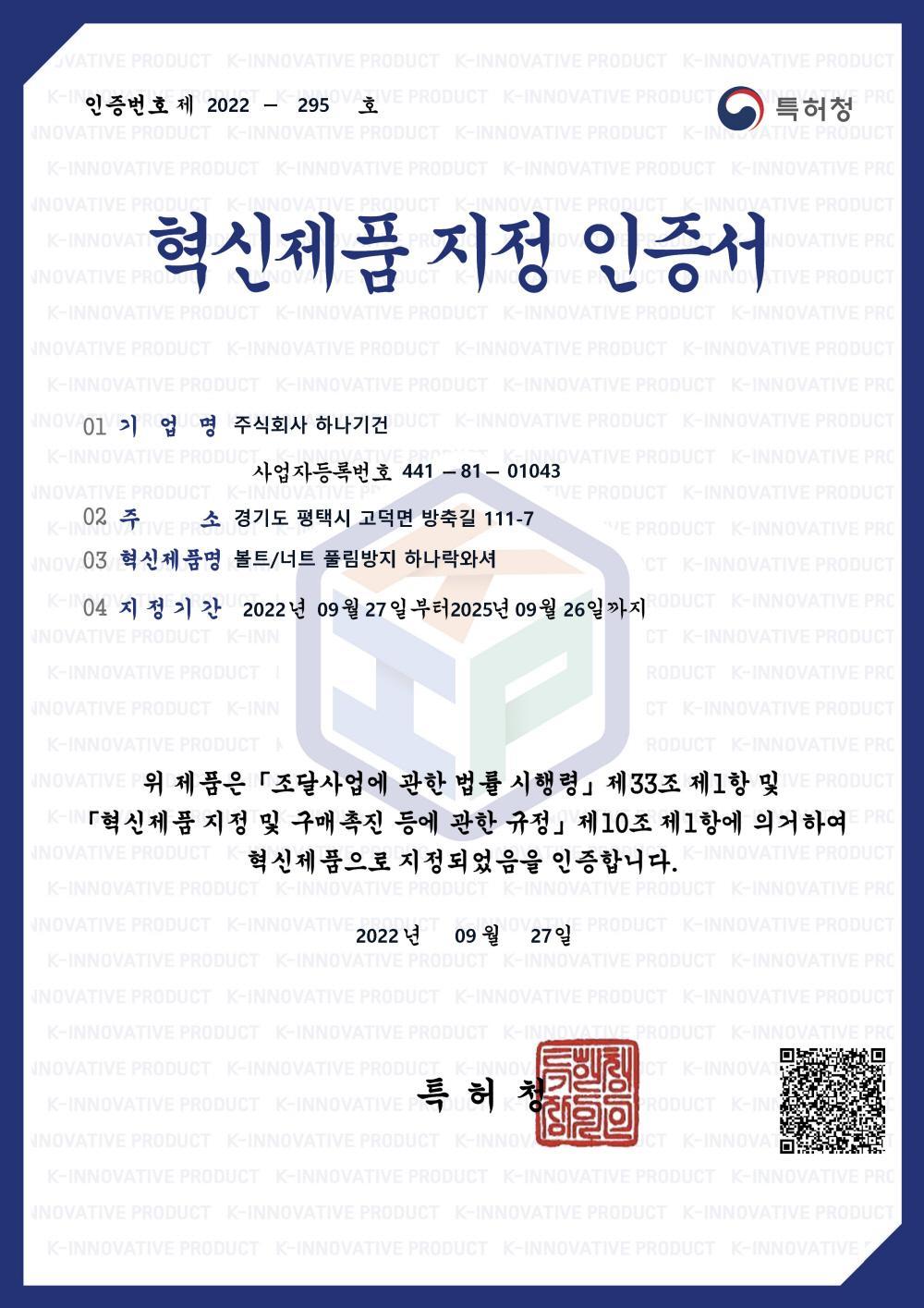

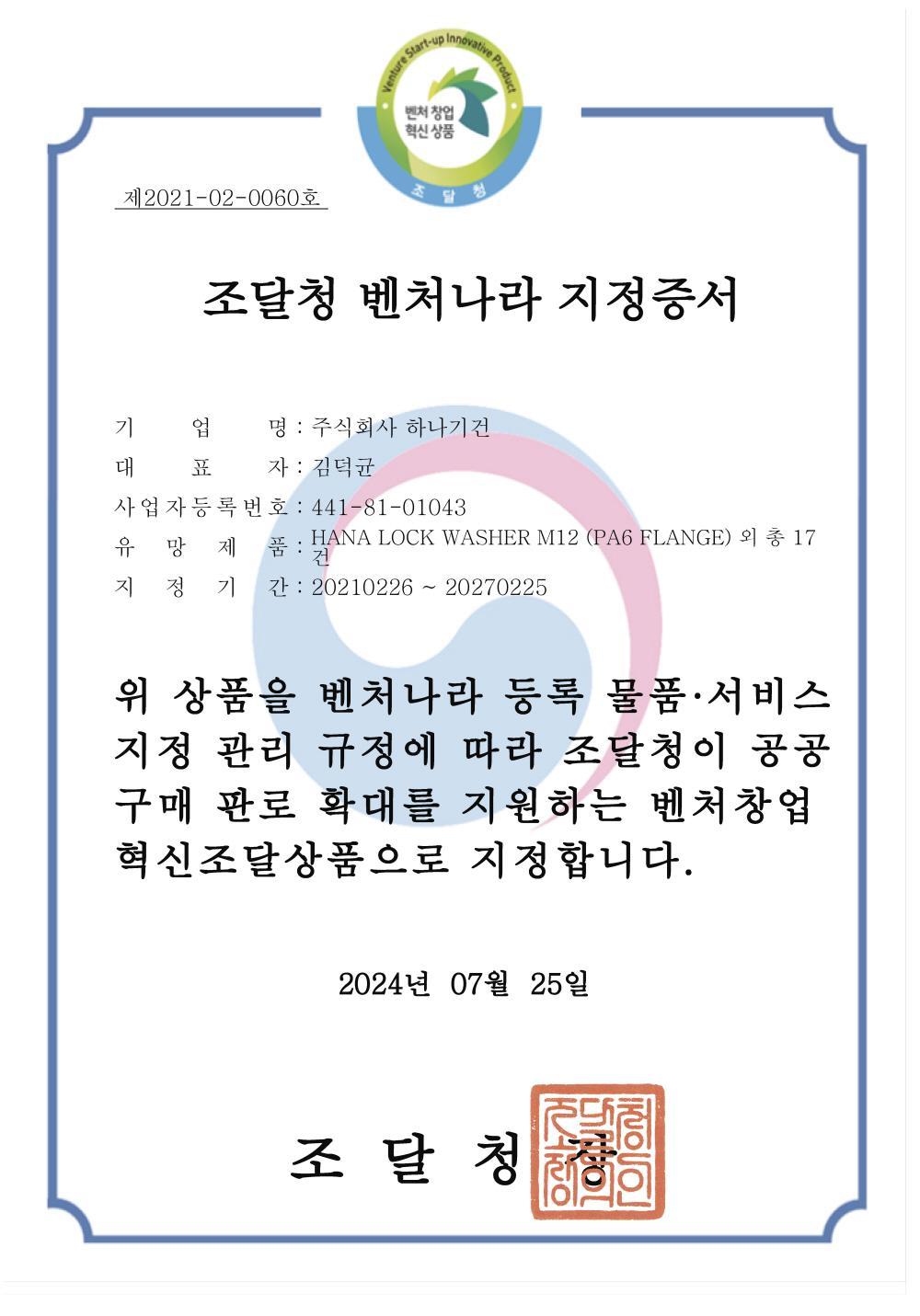

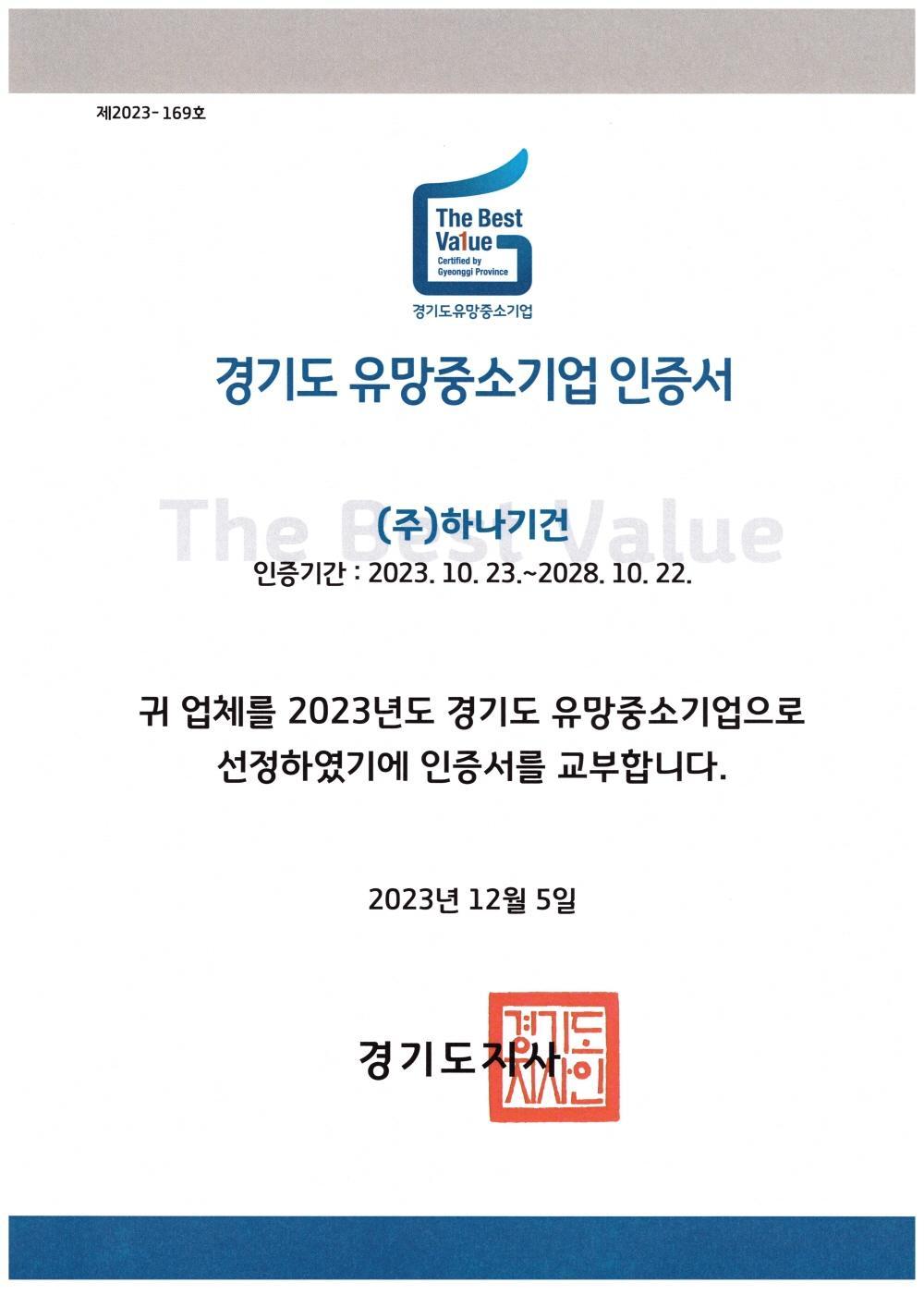

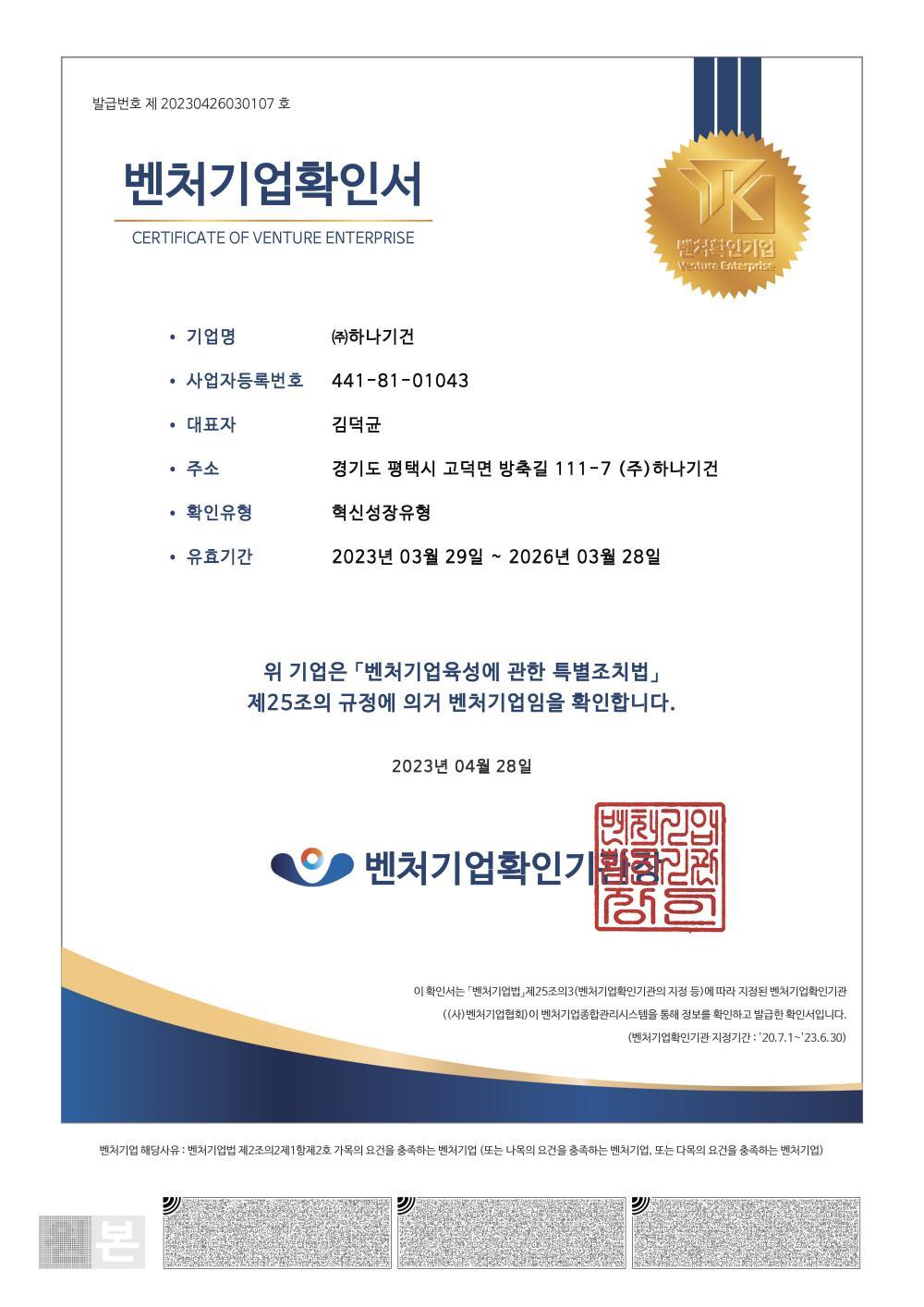

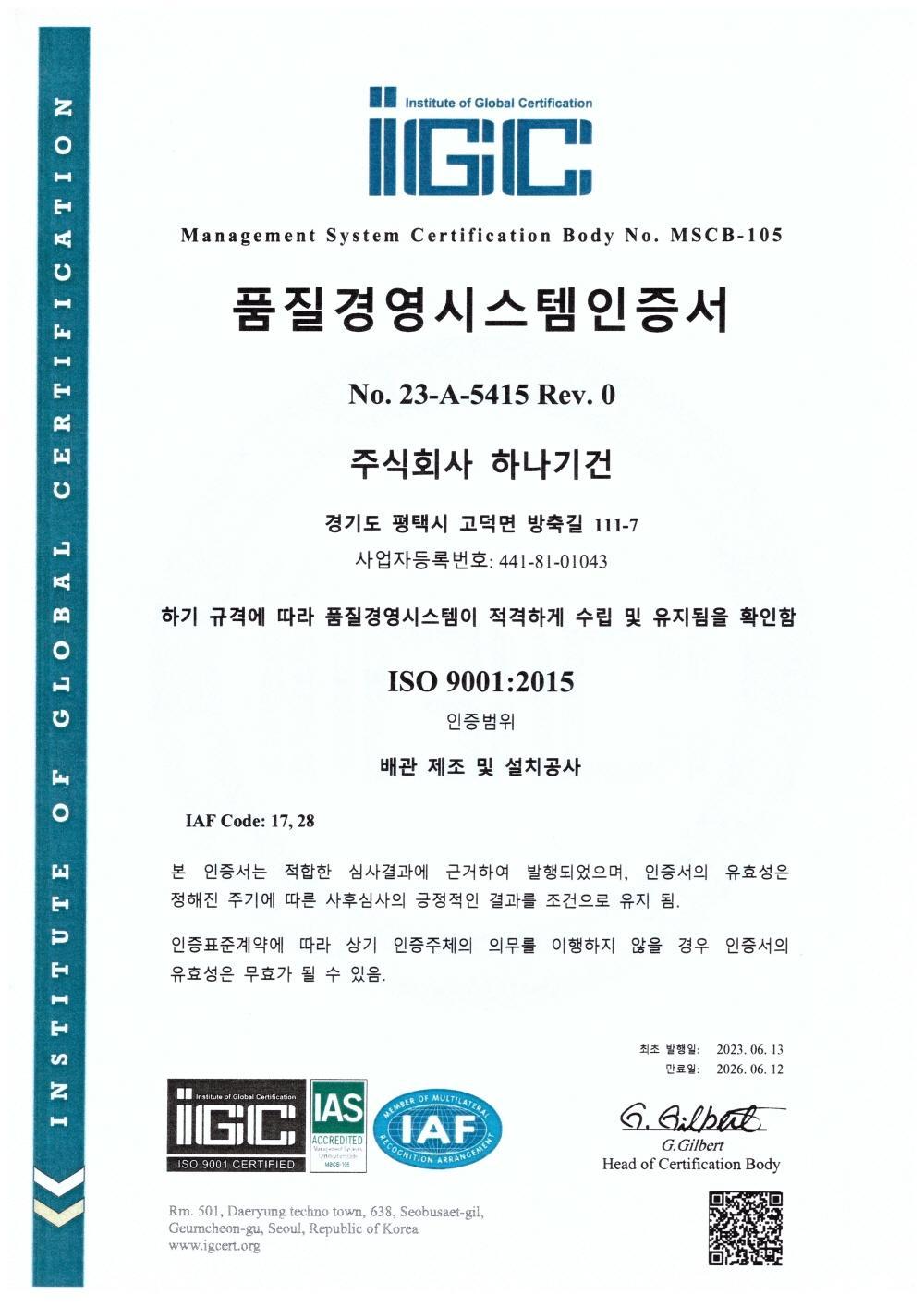

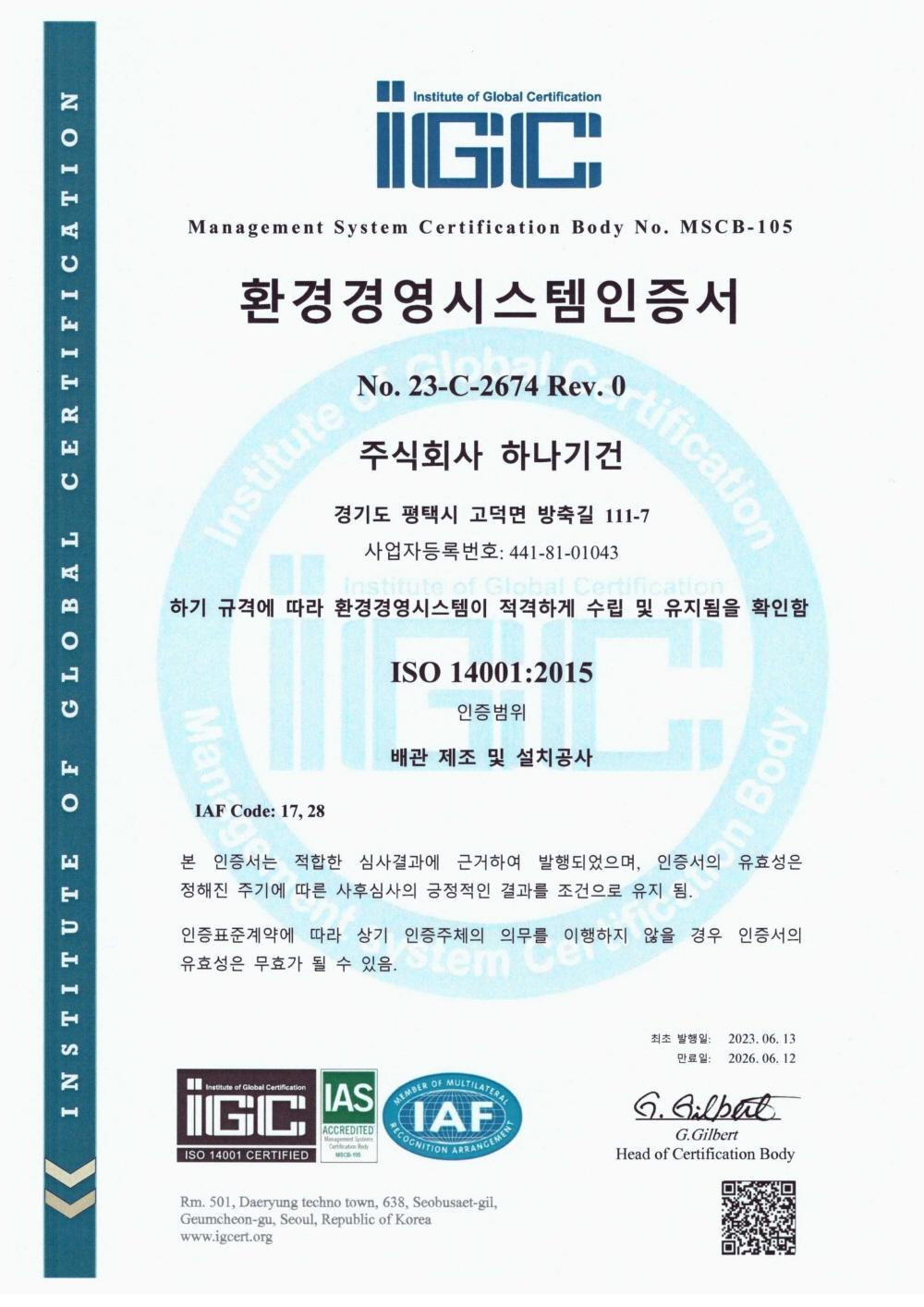

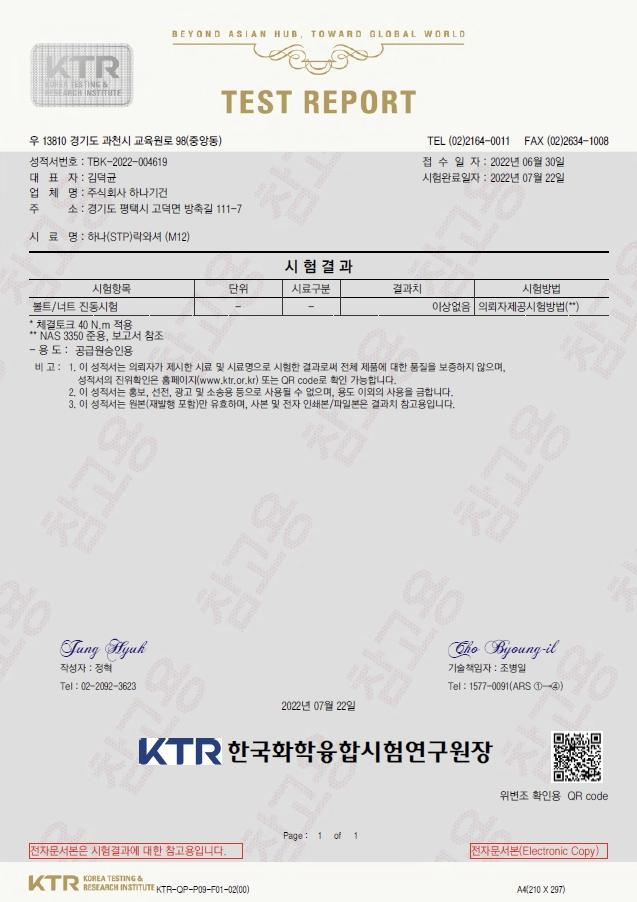

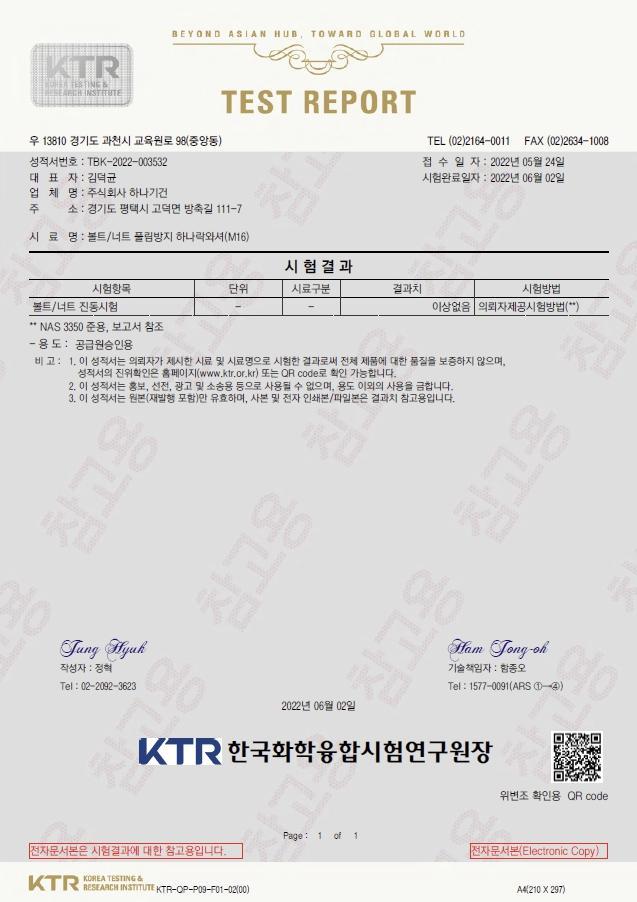

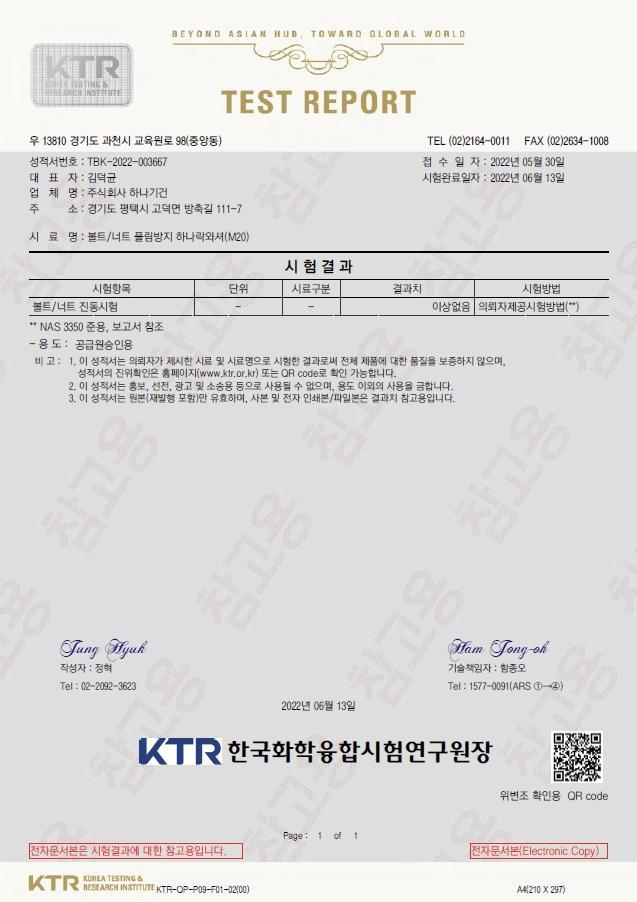

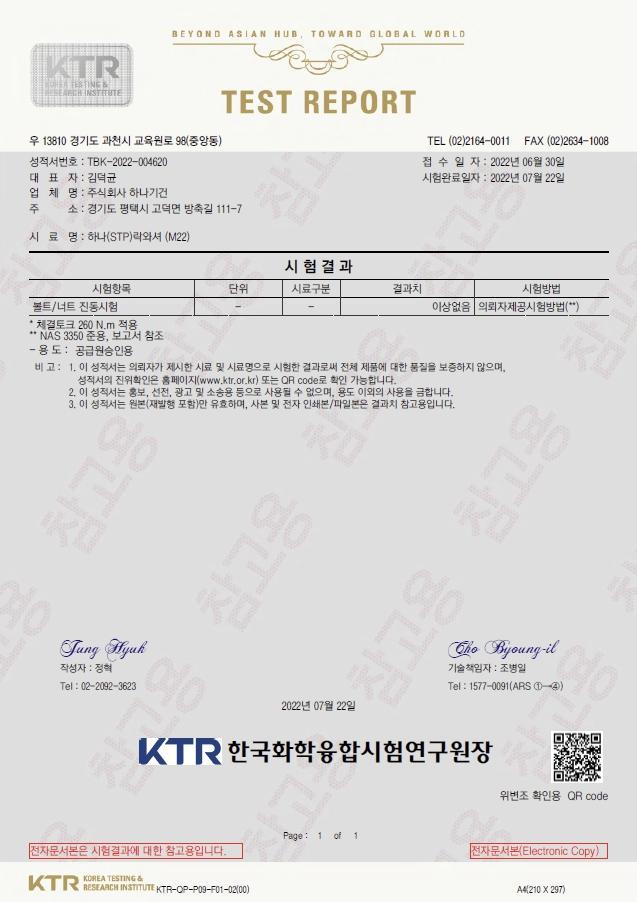

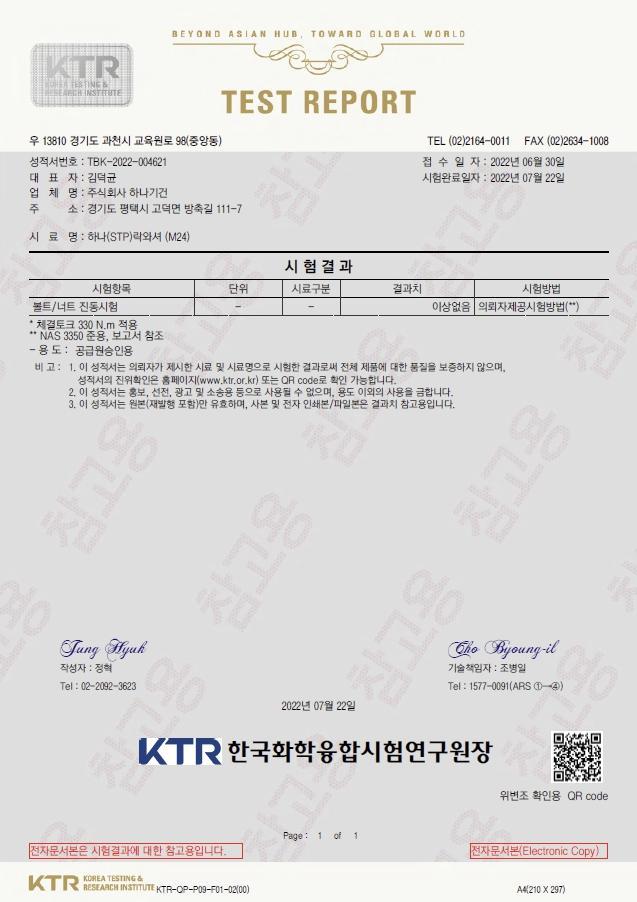

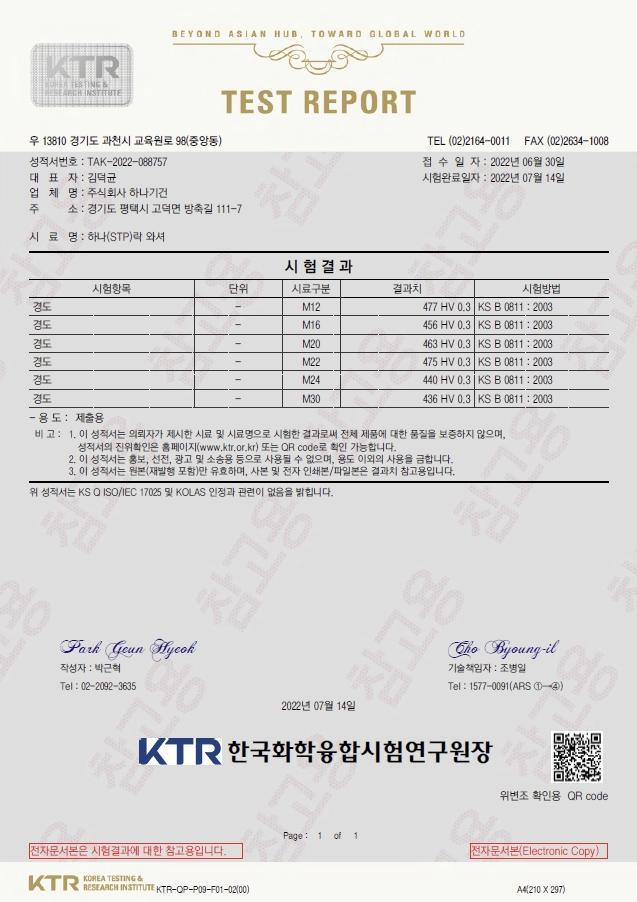

• Accordingly, Hana Lock has been certified as a reliable product for implementing a safe site through the KTR vibration test (NAS3350) by an authorized certification agency, and provides a complete solution for bolt/nut loosening prevention.

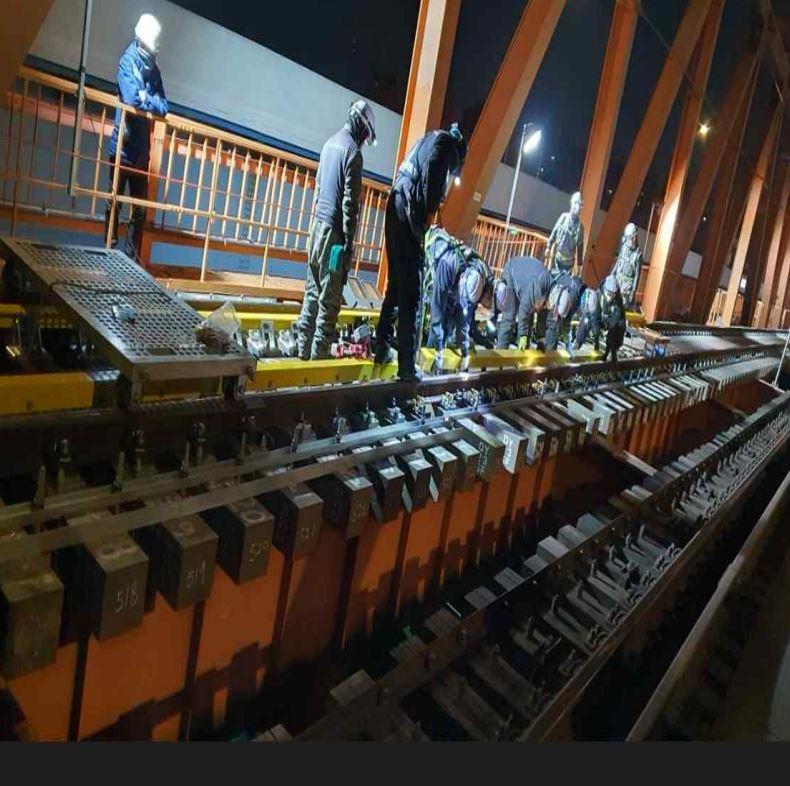

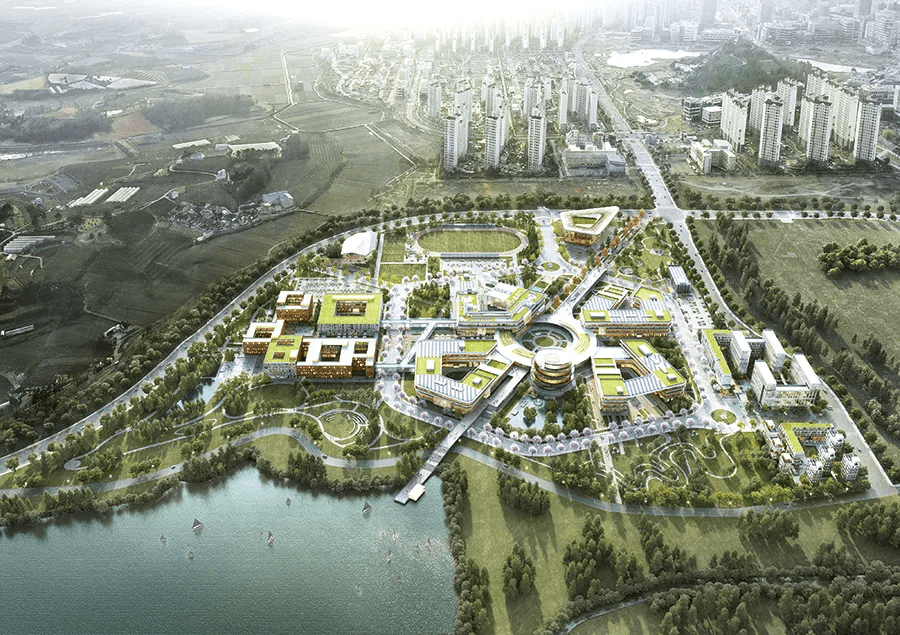

• Applicable to all fields where bolts/nuts are used (machinery, equipment, and piping equipment, steel structures, oil refineries, chemicals, gas, marine plants, ships, railways, bridges, aerospace, and defense industries)

한국어

한국어